SAFE

HEPA (High Efficiency Particulate Air) safe filtration technology.

INNOVATIVE

Real time filter monitoring, air flow monitoring with advanced filtration.

ECO-FRIENDLY

Engineering green products that protect the environment since 1992.

Founded in 1997, Syngene is a world-leading supplier of gel doc systems for rapid imaging and accurate analysis of visible gels, multiplexed fluorescence westerns, stain-free gels and chemiluminescent blots.

Our relationship was formed in 2019 when Airclean sought a new European distributor for their range of PCR workstations. Since then, Syngene has taken on more of the Airclean range, and we now dual brand the systems to bring the safe ISO Level 5 Class 500 units to a global market. Trust Syngene and AirClean to provide you with a safe and efficient solution.

Founded in 1992, AirClean Systems is the largest North American manufacturer of ductless hood, workstations and enclosures. We continue to develop and produce a complete range of solutions for protecting the operator or process from toxic vapours, fumes, gases and particulates.

AirClean Product Range

AC600 Series Class 1 Biological Safety Workstation

Safely handle biological sample

No installation required - plugs directly into a standard 110V or 220V electrical outlet

AirMax Total Exhaust Fume Hood

Consistent flow, corrosion-free hood.

Constant monitoring of fume hood face velocity with variable airflow control to user preset value

Dead Air Box

A reliable and safe option for amplifying and manipulating DNA/RNA.

No installation required - plugs directly into a standard outlet

Ductless Chemical Workstation

Flexibility and mobility for today's ever-changing laboratory environment.

Constant monitoring of fume hood face velocity with variable airflow control to user preset value

DuraMax Total Exhaust Laminar Flow Hood

Perfect for stong acids or trace metal analysis.

Filter and electronics are located above the workspace, eliminating the chance of a chemical spill entering these sensitive areas

Endeavour Ductless Fume Hood

Monitoring and control at the touch of an icon.

AirZone baffling directs toxins away from the operator in a predictable pattern, eliminating "dead spots"

Horizontal Laminar Flow Clean Bench

Perfect for ISO 5 applications.

Polypropylene construction for chemical resistance: NO RUST

Microscope Enclosure

Operator and process protection for microscope applications.

Optional one or two filters depending on your desired purity level

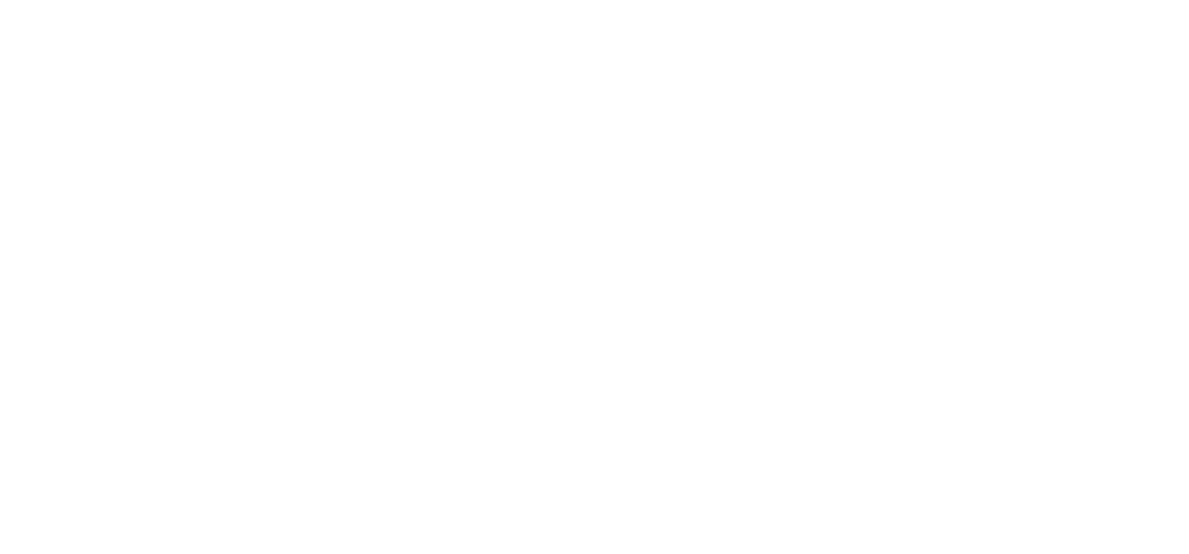

PCR Workstation

Get results - not background.

- No ductwork or installation required - Choice of standard or tall version UVTect® microprocessor controller - ISO 5 vertical laminar flow air - Seamless plastic design - no joints - UV shelf with built-in pipettor holder

Polypropylene Ductless Fume Hood

Perfect for the largest range of applications.

For containment of virtually any toxic vapour, fume, gas, or particulate

Polypropylene Free-Standing Ductless Enclosure

Extra vertical height from a proven ductless filtration platform.

Wide range of bonded activated carbon and HEPA filters for containment of virtually any toxic vapour, fume, gas, or particulate

Polypropylene Total Exhaust Fume Hood

The perfect alternative to a ductless hood, workstation or enclosure.

Constructed from thermally fused polypropylene with folding polycarbonate sash

PowderSafe Enclosure

Compact, mobile solution for powder containment.

Electrostatically charged pre-filter prevents ‘particle rain’

Robotic Enclosure

Custom-fitted to your robotic equipment.

Self-contained with no ductwork required

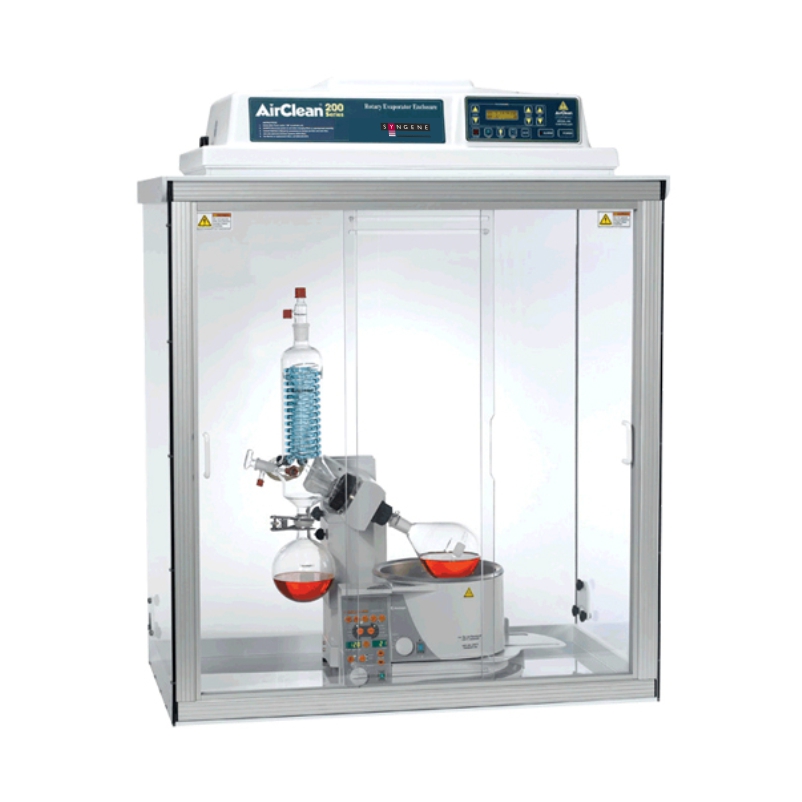

Rotary Evaporator Enclosure

Perfect for enclosing your laboratory apparatus.

Our AirSafe automatic safety controller continuously checks the airflow and filter conditions to ensure safety

TeachAide

Protecting both teacher and student by offering 360°, view.

Clear polycarbonate shell for 360° visibility

Vertical Laminar Flow Enclosure

Extra height and depth for large applications.

Polypropylene construction for chemical resistance: NO RUST

Vertical Laminar Flow Workstation

Compact, portable and meets the standards of ISO 5.

HEPA filter monitor automatically indicates when a filter change is required

Applications

Cytology

The study of the structure and function of cells is called cytology. It is a widely used technique in the medical field for diagnosing cancer and infectious diseases and screening for foetal abnormalities. Researchers working with clinical samples or model organisms may also use cytology methods. The practice of cytology can be divided into two categories based on the sample collection method.

Exfoliative cytology involves collecting cell samples by scraping, brushing, or naturally shedding from the body (such as urine, mucus, saliva, etc.). Examples of exfoliative cytology include swab-based tests for COVID-19 and Influenza, urinary tract infection and cancer tests, and cervical screening.

On the other hand, Interventional cytology examines samples collected from inside the body, such as fine needle aspiration from a cyst or any other internal nodule.

Typically, samples are analysed using either staining or molecular methods. For staining methods, the cell samples are transferred to a slide and fixed with formalin, formaldehyde derivatives, or alcohol (methanol, ethanol). Cytological staining of artificially coloured cells can aid researchers and clinicians in screening, identifying and diagnosing several pathological conditions. A wide variety of cytological stains are available, including Pananicolaou, hematoxylin and eosin (H&E), Giemsa stain, Prussian blue, and Congo red.

Many stains used for cytological methods are considered hazardous chemicals that are flammable and cause serious eye or skin irritation or are carcinogenic. Vapours from fixatives such as formalin and paraformaldehyde can also cause eye, nose, and throat irritation, even when exposed to low levels for a short period of time. Repeated exposures may cause some people to develop allergic reactions to formaldehyde-based compounds. Similarly, methanol vapour inhalation can cause issues with the central nervous system, such as nausea, drowsiness, and headaches. Severe methanol exposure can even lead to permanent vision changes and blindness.

Handling of any hazardous fixatives or stains should be completed under a fume hood while wearing appropriate personal protective equipment (PPE). To ensure the operator’s safety while providing flexibility in workspace setup, ductless fume hoods with a horizontal laminar flow are an excellent option. Equipping them with appropriate carbon filters to capture any chemical vapours before the exhaust enters the room protects the operator and others nearby. Let’s prioritise safety while performing these essential cytological methods so that everyone involved can work with peace of mind.

- AC600 Series Ductless Chemical Workstation

- Polypropylene Ductless Fume Hood Folding Sash

- Polypropylene Ductless Fume Hood Sliding Sash

- Endeavour Ductless Fume Hood Folding Sash

- Endeavour Ductless Fume Hood Sliding Sash

Epoxy Resins

Epoxy resins, an ingenious invention by Dr Pierre Castan and Dr Sylvan Greenlee, have come a long way since their early days in dental fixtures. Today, they’re the backbone of manufacturing, widely used in construction, woodworking, and manufacturing industries. Epoxy resin is made up of two parts: a synthetic polymer material that contains an epoxide group. When mixed, it undergoes a chemical reaction resulting in a durable, high strength and adhesive substance.

Epoxy resins provide a waterproof barrier, high heat resistance, strength, and many other benefits. However, proper handling and safety precautions are crucial due to the potential hazards associated with specific formulations.

The process of curing epoxy resin can pose many hazards to operators, including the release of harmful vapours and the inhalation of small particles. However, by implementing proper engineering controls, we can protect operators and ensure their safety. By using enclosures like ductless hoods or local exhaust ventilation, we can mitigate the risks associated with epoxy resin curing and create a safer environment for all involved to protect our operators and promote a culture of safety in all manufacturing processes.

Epoxy resins can be hazardous to work with, so it’s important to manage vapours to protect operators. A ductless fume hood with horizontal laminar flow can help pull air from near the operator and filter contaminated air. Carbon and HEPA filters may be needed to capture all the dust in the air. Alternatively, a ducted fume hood can be used but may require ductwork.

- Endeavour Ductless Fume Hood Sliding Sash

- Endeavour Ductless Fume Hood Folding Sash

- Polypropylene Ductless Fume Hood Sliding Sash

- Polypropylene Ductless Fume Hood Folding Sash

IV Therapy

Intravenous (IV) therapy involves delivering medication directly into a patient’s vein. IV therapy is delivered into someone’s vein as it is the fastest way to get it working in the body. During treatment with an IV drip, fluids, medicine, nutrition, or blood are delivered directly into the bloodstream by inserting a small plastic catheter into a vein.

IV fluids are an essential component of medical treatment. The basic IV fluids consist of saline solutions, glucose, or combinations of saline with buffers or electrolytes. However, some treatment plans require adding additional nutritional components or medications to these base solutions. These more complex fluids can be bought pre-mixed or mixed by a pharmacist or other medical professionals to create an IV admixture.

Mixing or compounding intravenous (IV) admixtures is a common procedure in hospital pharmacies. Some medications are not stable in liquid form and must be stored as powders mixed with a diluent before being added to an IV fluid bag. In other cases, a patient’s treatment plan may require a specific mixture or dosage of medication(s) that is not commercially available.

Compounding admixture to prepare IV fluids is a type of pharmaceutical compounding. Therefore, it is crucial to follow sterile compounding guidelines to ensure patient safety. Pharmacists perform this process in a designated cleanroom that contains a primary engineering control (PEC). PECs like laminar airflow workbenches/hoods, compounding aseptic isolators (CAIs), and compounding aseptic containment isolators (CACIs) are critical in preventing contamination of the IV fluid during the compounding process.

Microbial contamination of IV fluids can lead to severe infections, sepsis, and/or septic shock, which can be fatal, with mortality rates ranging from 20-50%. A properly cleaned PEC prevents cross-contamination of the IV fluid and medications with other compounds in the area or room. Cross-contamination can result in drug interactions that can compromise patient safety.

To ensure a sterile compounding environment, the PECs (Primary Engineering Controls) must have ISO Class 5 standard airflow, which means there should be no more than 3,520 particles (0.5µm or larger) per cubic meter. The PECs are equipped with high-efficiency particulate air (HEPA) filters to remove particles from the air that enters the workspace.

Laminar flow hoods are designed to protect the process but not the operator. Air enters the hood from the back or top and is HEPA-filtered before entering the workspace. The air from the workspace is then exhausted through the front of the hood, away from the operator. It’s worth noting that laminar flow hoods are not suitable for compounding hazardous chemicals like chemotherapy medications.

The choice of a hood with horizontal or vertical airflow depends on the pharmacy’s needs, operator, work area, and environment. Horizontal laminar flow hoods have a larger opening, which is less restrictive to operator movement. On the other hand, vertical laminar flow designs tend to have a front sash, creating a smaller workspace opening. However, the vertical laminar flow hood sash offers slightly more protection against potential splashes. It can be closed after use and cleaning to prevent airborne particles from entering the workspace.

- Vertical Laminar Flow Workstation

- Polypropylene Horizontal Laminar Flow Clean Bench

- Polypropylene Vertical Laminar Flow Enclosure

Powder Handling

Powder handling is a crucial process that involves weighing or transferring powders from one container to another. It is a vital step in manufacturing a wide range of products, including cosmetics, foods, beverages, and pharmaceuticals. Powder handling is a common task in different fields, industries, and professions, especially in laboratories.

Handling powders can be a messy and potentially hazardous task, especially when dealing with fine powders that easily become airborne, creating dust that can be inhaled. Inhaling certain chemical powders can cause damage to the nose, mouth, throat, or lungs, especially if exposure is repeated or prolonged. It is important to take precautions and wear protective equipment when handling powders to avoid any harmful effects they may cause.

When working with powders, protecting the operator and others in the area is important. Hoods and enclosures are essential for this purpose. A horizontal laminar flow hood can significantly reduce the risk of powder escaping. Additionally, filters installed within the hoods and enclosures prevent powder particles from being released into the environment, minimizing the risk of nuisance odours.

To ensure maximum protection, operators should always wear appropriate personal protective equipment (PPE) and work within a properly fitted hood or enclosure with the appropriate filters.

- Powdersafe Type A Enclosure

- Powdersafe Type B Enclosure

- Powdersafe Type C Enclosure

- Powdersafe Bulk Handling Enclosure

Soldering

Soldering is a common joining process used to fuse different types of metals together by melting a metal alloy called solder. Typically, solder is composed of tin and lead, but with RoHS regulations in place, lead-free soldering has become more popular. Soldering is widely used in plumbing, electronics, and metalwork, from flashing to jewellery and musical instruments.

To create a solder joint, a low-melting metal alloy is heated above its melting point using a heated soldering iron, soldering gun, or solder pot. Once melted, the solder flows and bonds the two metal pieces together.

However, sometimes impurities such as oil, dirt, or oxidation may be present at the joint site. Flux can help prevent oxidation and can chemically clean the metal. The flux used is rosin, a natural resin extracted from pine trees, which helps to strengthen and improve the electrical contact of electrical joints mechanically.

Soldering can produce dust and fumes, which can be hazardous. If using flux-containing rosin, it can produce fumes that, if inhaled, can cause eye and upper respiratory tract irritations. Moreover, some of these chemicals are flammable, which poses a safety risk due to the accumulation of flammable fumes near a heated element like a soldering iron, gun, or pot. The fumes from lead-based soldering carry an additional risk of lead poisoning, especially when exposed extensively or repeatedly. Lead exposure can cause severe neurological problems, as it targets the brain and central nervous system.

It is crucial to contain the hazardous fumes that are released from flux and solder in the workspace to ensure the safety of operators and others in the work area. Ductless fume hoods offer greater flexibility in workspace setups and can provide hazardous fume containment better than their ducted counterparts. When soldering, it is important to use a hood with a horizontal laminar flow that pulls air from near the operator, across the workspace, and up to the top of the hood to protect the operator. The hood should be equipped with a high-efficiency particulate air (HEPA) filter to capture dust particles and an appropriate carbon filter to capture chemical vapours before air exhausts into the room.

A total exhaust fume hood with a similar airflow pattern could also be used if building ductwork is available. Operators should always follow safe soldering practices to prevent burns and wear the appropriate personal protective equipment (PPE).

Solvent Mixing

It is crucial to take precautions when working with solvents in order to protect yourself and others from harmful chemicals and odours. One effective way to do this is by using a fume hood.

A fume hood with horizontal laminar flow can be used for solvent mixing applications. This type of hood pulls air away from the operator across the workspace and directs it to the back of the hood. The contaminated air is then redirected to an exhaust area at the top of the hood. Filters can be installed before the air exhausts into the room to capture particulates and fumes, which protects everyone in the vicinity and controls nuisance odours.

The sash (window) lets you view and manipulate objects within the enclosure while keeping fumes from toxic or volatile chemicals away from your face.

Another option is to use ducted vertical flow hoods, which blow HEPA-filtered air from the top of the hood onto the work surface. The contaminated air is then directed to an exhaust duct, where it can be scrubbed to remove contaminants before being released into the environment. It’s important to design the airflow of the vertical flow hoods to prevent contaminated air from flowing under the sash into the room.

Although fume hoods can provide some protection, wearing personal protective equipment when working with hazardous materials is essential.

- AC600 Series Ductless Chemical Workstation

- Polypropylene Ductless Fume Hood Folding Sash

- Polypropylene Ductless Fume Hood Sliding Sash

- Endeavour Ductless Fune Hood Folding Sash

- Endeavour Ductless Fume Hood Sliding Sash

Spraying

Spraying is a painting technique that employs a spraying device, typically coupled with compressed air, to airspray an item with a thin coat of coating. A wide range of coatings are available, including paint, ink, varnish and other materials. Airbushes and spray guns are the main devices used for industrial spraying.

Epoxy resins consist of a broad family of chemicals used in various industrial areas (adhesives, paints, coating and sealants). Spray adhesives are employed for bonding components, laminating materials, and securing various substrates, whether in the production of electronics, appliances, furniture, or packaging.

Spray paints contain hazardous elements called volatile organic compounds (VOCs), e.g. commonly Acetone, Xylene and Toluene. The inhalation of VOCs is possible through the spray paint fumes when spraying paint with compressed air. Exposure to these chemicals can cause damage to vital organs like the eyes, throat, lungs, brain, liver, and kidneys. Many spray paints and adhesives are flammable, which poses a significant safety risk. The accumulation of flammable fumes can lead to a fire outbreak.

Epoxy resins can also be hazardous to health. Skin contact is the main route of exposure, which can result in contact dermatitis through irritation or sensitisation, and the other route is through dust generated during the process of using epoxy resins, which may cause respiratory irritation.

When spraying, operators work inside a ventilated enclosure known as a spray booth to protect themselves from spray aerosols. Spray booths come in various sizes and designs, and commercial options are equipped with safety features to ensure the safety of operators and others in the vicinity.

A ductless hood can be used as a spray booth for smaller-scale applications. This hood type should have a horizontal laminar flow that pulls air from near the operator, across the work surface, and up to the top of the hood to protect from aerosols and fumes. To capture vapours and aerosols before air exhaust, the hood must be fitted with appropriate high-efficiency particulate air (HEPA) and carbon filters. Ductless hoods are enclosed, which makes it easier to contain sprayed products for cleanup.

- Polypropylene Free Standing Ductless Enclosure

- Polypropylene Ductless Fume Hood Folding Sash

- Polypropylene Ductless Fume Hood Sliding Sash

Titrations

Titration is a quantitative analytical technique used to determine an unknown solution’s concentration by using a known concentration. The unknown solution, known as the analyte, is mixed with the solution of known concentration, called the titrant until the reaction is complete. The volume of the titrant added is measured to determine the concentration of the unknown solution. An indicator is often used to signal the endpoint of the reaction.

Titration is used in various industries, including food and pharmaceuticals, for processing and developing products. It is particularly useful for calculating the precise amount of salt, Vitamin C, or Vitamin E in food items.

There are different titration methods, with the acid/base and reduction/oxidation methods being the most common. The acid/base method is also known as a neutralisation reaction, where pH indicators are used to determine the endpoint. In contrast, reduction/oxidation titration involves a reaction between a reducing agent and an oxidising agent, often utilising a redox indicator.

Titration experiments often involve handling hazardous, toxic, and corrosive substances. The primary concern is the risk of severe skin burns and eye damage caused by acids and bases present in the samples or used as titrants. These chemicals can also cause respiratory irritation. Potassium permanganate, commonly used in reduction/oxidation reactions, can also cause coughing or shortness of breath by irritating the nose, throat, and lungs.

In addition, many of the colour indicators used to observe colourimetric endpoints are classified as potential carcinogens. When assessing the safety risks involved, it is essential to consider the potential reaction products that may form during the titration process.

When performing titrations, it is paramount for operators to wear the appropriate personal protective equipment. One effective way to protect oneself and others from hazardous chemical fumes is to use a fume hood. A ductless fume hood with a horizontal laminar flow is suitable for most applications. However, it is essential to verify the chemical compatibility of the hood with the manufacturer before use. The horizontal laminar flow should move air away from the operator’s vicinity, across the workspace, and towards the top of the hood. The hood must be equipped with an appropriate carbon filter to trap the fumes created by the titration chemicals and reaction products.

In some cases, a high-efficiency particulate air (HEPA) filter may also be required. After the contaminated air reaches the top of the hood, it should pass through the carbon filter before being exhausted back into the room. Alternatively, a ducted hood may also be used.

- AC600 Series Ductless Chemical Workstation

- Polypropylene Ductless Fume Hood Folding Sash

- Polypropylene Ductless Fume Hood Sliding Sash

- Endeavour Ductless Fume Hood Folding Sash

- Endeavour Ductless Fume Hood Sliding Sash